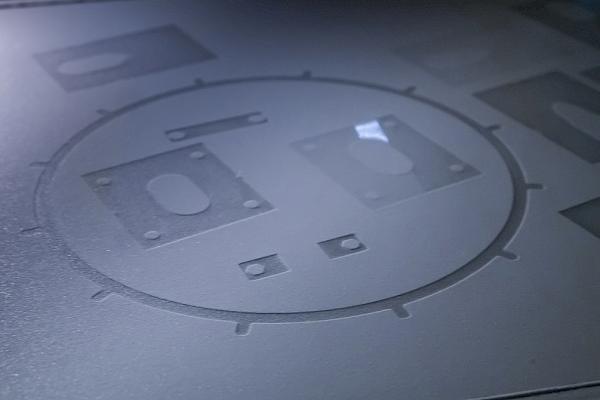

Metals ‒ Powder Bed Process

Powder and material qualification, AM-ready material concepts and process development for additive manufacturing processes

Metals ‒ Direct Metal Deposition

Powder and material qualification, AM-ready material concepts and process development for additive manufacturing processes

Plastics & Ceramics

Material and process development for plastic and ceramic powders for industrial AM processes

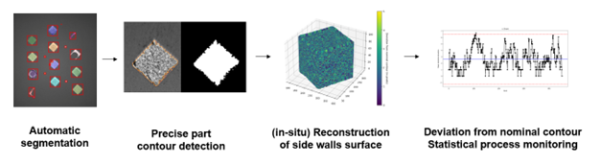

Statistical process control, Process optimization

Our team enhances Powder Bed Fusion (PBF) reliability using an intelligent feedback control system, leveraging computer vision and sensor fusion for optimal manufacturing

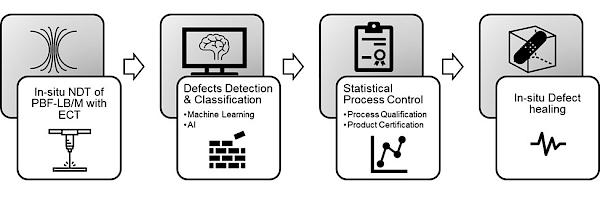

Non-Destructive Testing (NDT), Eddy current sensing (EDC)

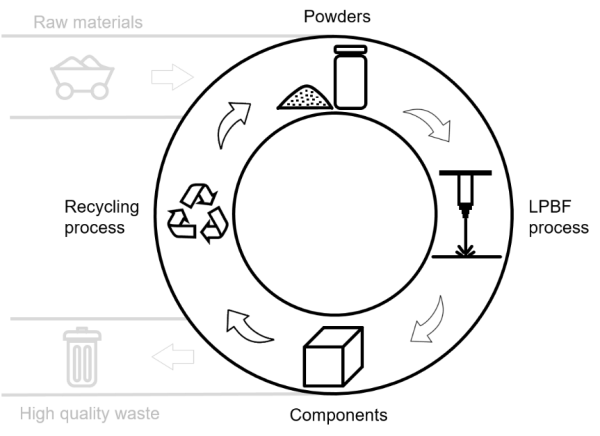

Powder production and characterization, Advanced alloys development, Recyclability of powder for PBF

Sensor integration and active damping

PBF-LB/M enables sensor integration in additive manufacturing, addressing challenges for diverse industrial applications

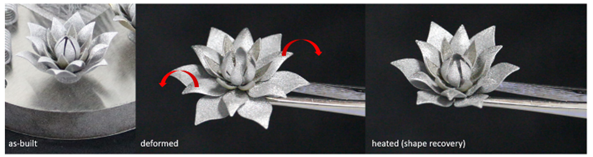

Shape memory alloys

NiTi via PBF-LB/M: Complex shapes, tailored properties for biomedical, aerospace, robotics. TWSME explored for novel applications.

Design for Additive Manufacturing

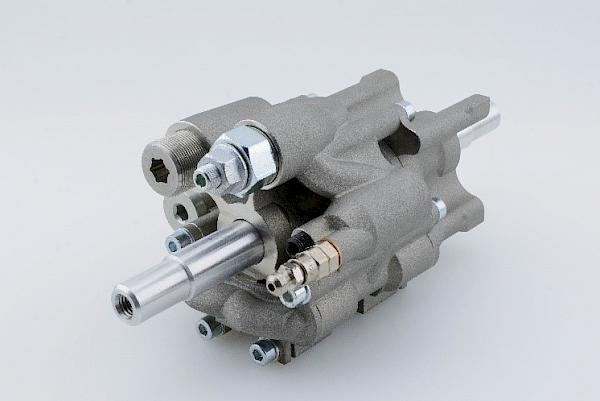

Consequent usage of the design freedom of the additive manufacturing (AM) technology in the product design phase

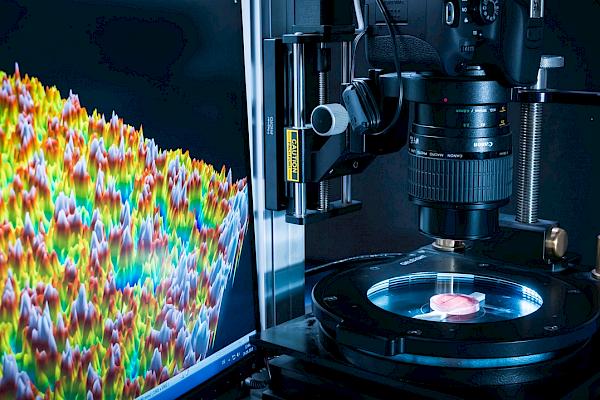

Finishing & Quality

Post-processing and quality assurance of AM components

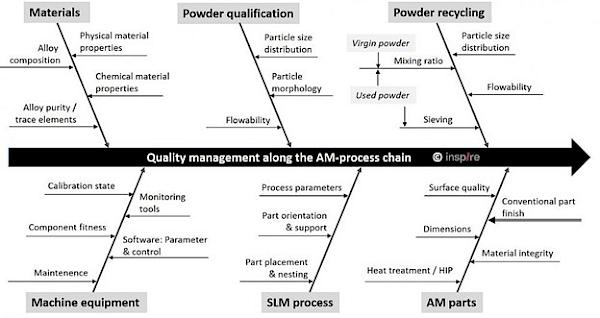

Quality Management Systems

Unsere vielfältigen Kompetenzen sind eine Voraussetzung für die Entwicklung des Qualitätsmanagements.