Additive manufacturing (AM) is a fast-growing technology that offers a high degree of design freedom. Additionally, AM enables the design of new products in digital value chains in an industrial context. To take the full advantage of AM, we consider the end-to-end process chain to developing new design tools, strategies and computational methods to enable AM access in a wide range of applications.

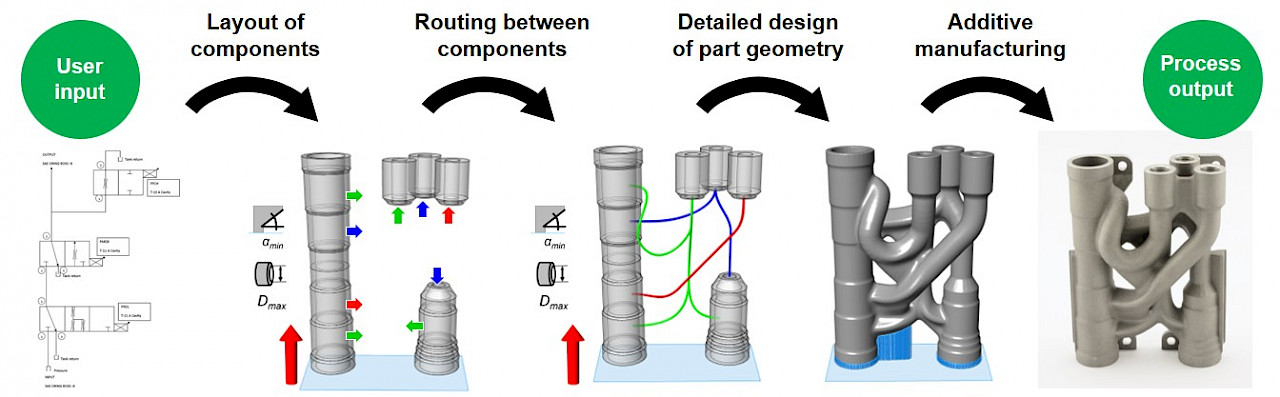

Design Automation for AM

The design of AM components requires knowledge, experience, and is time and cost intensive. To support the designer and reduce the design effort, we develop methods and tools to automate the design process.

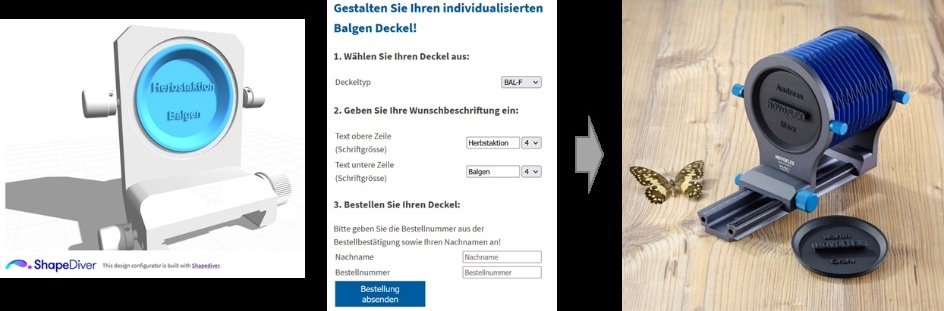

Design Configuration for AM

For many AM applications, the design process represents the biggest bottleneck for end-users. To simplify automated design generation for novices, we develop design configurators based on physical models and new business models. The configurators enable complex design generation without in-depth programming knowledge or prior experience in the field of Design for AM.

Post Processing Strategies in AM

The main challenges in the as-built quality of AM include the adherence to precise geometrical accuracy and high-quality surface roughness. While AM enables the production of highly complex parts, conventional manufacturing technologies still are the ones that enable high precision. Conventional manufacturing technologies however are often time- and cost intensive. We develop strategies that combine different production processes under consideration of the entire AM process chain to facilitate and reduce post-processing. The strategies are validated in an end-to-end process chain.

Design for AM implementation

To increase the value of products and services through AM, we support companies in the introduction of AM in complex application fields. Within projects, workshops and general consulting we identifying new AM applications, the development of the design and new business models.

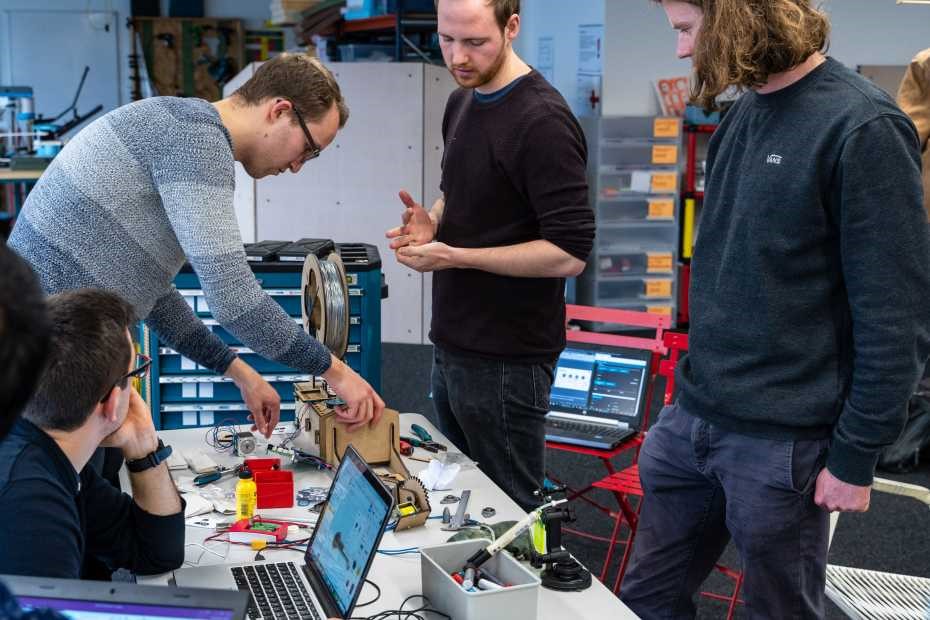

Agile for Hardware Development Training

While agile methods have proven to be very effective for the development of software, fundamental characteristics of physical products hinder the direct translation to the hardware domain. We have developed a training that simulates a hardware development project to teach principles of agile in a realistic and immersive way. Participants in groups of four design, manufacture and test modifications for the technical system within an authentic engineering and production setting. The training mimics typical roles, processes and tools of industrial engineering teams to realistically reflect the challenges of applying agile Hardware Development (AHD).