Active and/or mobile products leave their ecological footprint mainly in the use phase. Their life cycle assessment can be improved through superior product characteristics.

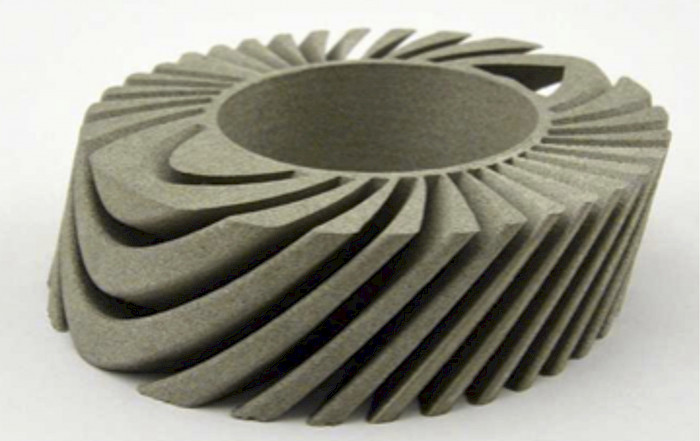

Efficient Coil Design with AM

Additive manufacturing allows a high degree of design freedom, which is used in this project to produce an ideal coil geometry for superconducting coils. The coil winding is being optimized to enable maximum field density. The coil design is being developed for particle accelerators and can equally be used to increase the efficiency of electric motors.

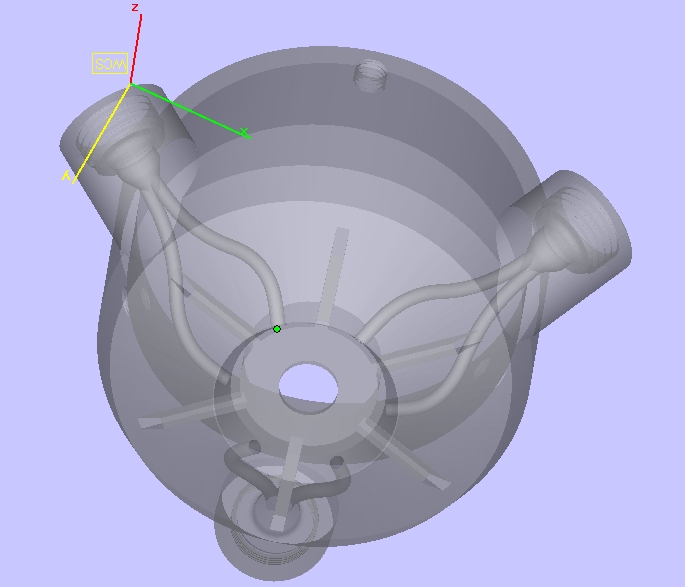

Extrusion Nozzle for Meat Substitutes

Plant-based meat substitutes have become popular for economic, environmental, ethical and health reasons. They reduce CO2 emissions by replacing animal meat with plant-based meat. Industrial production is based on extrusion cooking, in which the hot protein-water mixture is fed into a die where the extrudate forms with a meat-like texture. By using the "complexity for free" of additive manufacturing, the nozzle design can be optimized. It was developed and validated in collaboration with ETH pdz for parallelized large-scale production.

Optimized Cooling Lubricant Nozzles

The efficiency and quality of machining operations, such as turning, milling or grinding, depend to a large extent on the targeted and sufficient supply of cooling lubricant to the process point. This goal can only be partially achieved with flexible universal nozzles. Particularly in the case of large cutting volumes and especially in grinding, the provision of application-specific nozzles for the supply of cooling lubricant is an effective measure for process improvement. The competences of process analysis and additive manufacturing are used in combination.