Researchers worldwide are working on new solutions to provide energy, especially in the form of electricity, heating and cooling power. For practical use, these technologies need to be produced in large quantities, which is a challenge for manufacturing.

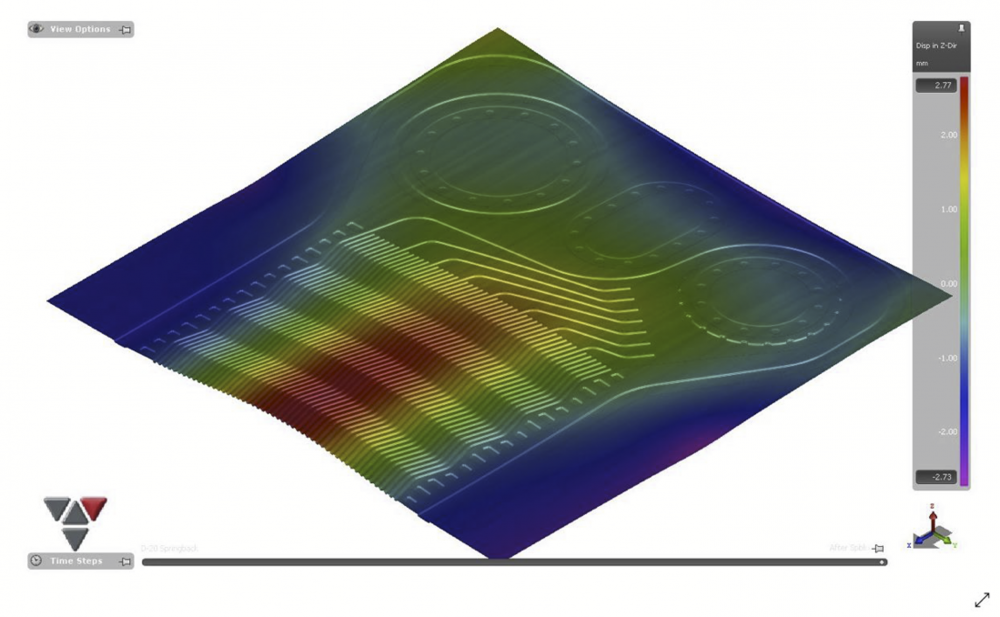

Mass Production of Bi-polar Plates

Today, electrification of vehicles is based on batteries, which are not a sustainable solution due to the necessary raw materials, especially cobalt and nickel. Fuel cells are an alternative that pose a major challenge in terms of manufacturing technology. For stacks of up to 400 units, metallic bipolar plates with fine channel structures must be manufactured with micrometer precision and in quantities of millions at low cost to be competitive with batteries. This goal can only be achieved with improved simulation methods for process optimization.

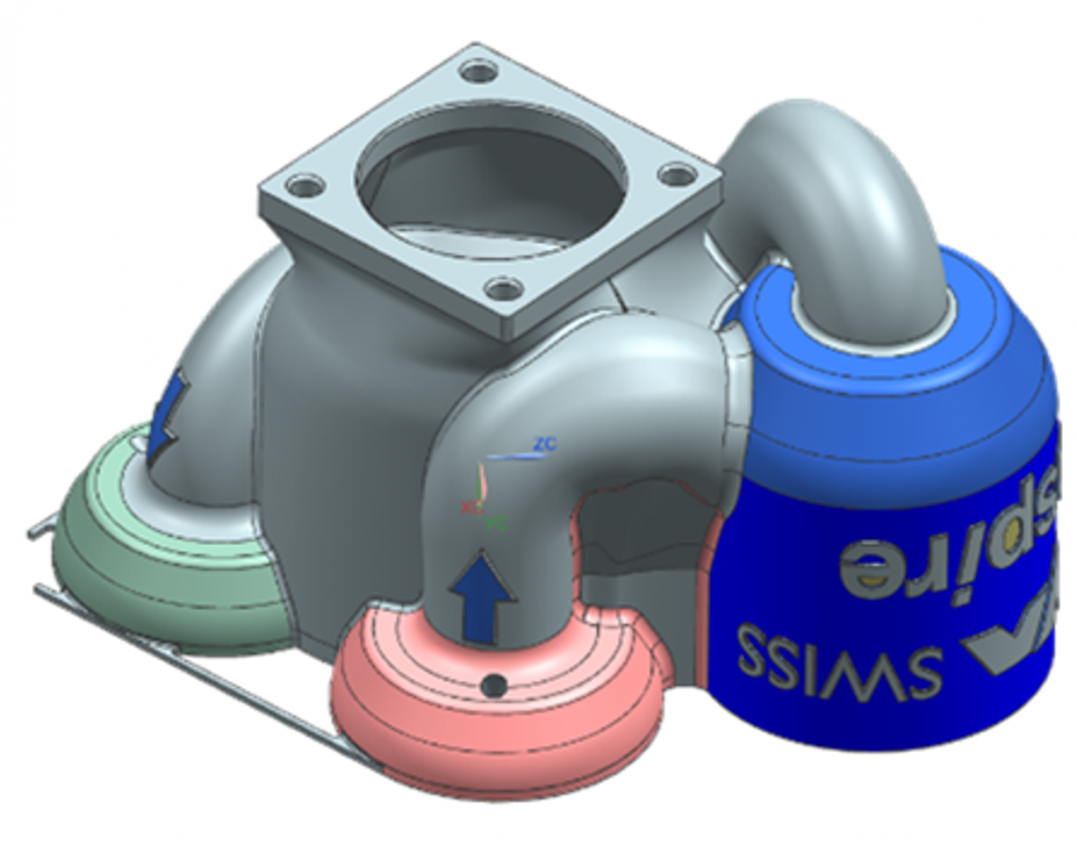

Intelligent High Pressure Valve for Hydrogen Filling Stations

Future mobility solutions using hydrogen as an energy carrier require H2 filling stations with valves that ensure tightness up to 1000 bar, are small in size and have integrated online condition monitoring. Using additive manufacturing, it was possible to develop a flow-optimized hydrogen valve that meets all these requirements.