Our core competence is the development and optimization of lightweight structures made of fiber reinforced polymers. To reach highly efficient lightweight structures we are concurrently considering lightweight materials, lightweight design, manufacturing processes and integration of functions.

Characterization of lightweight materials

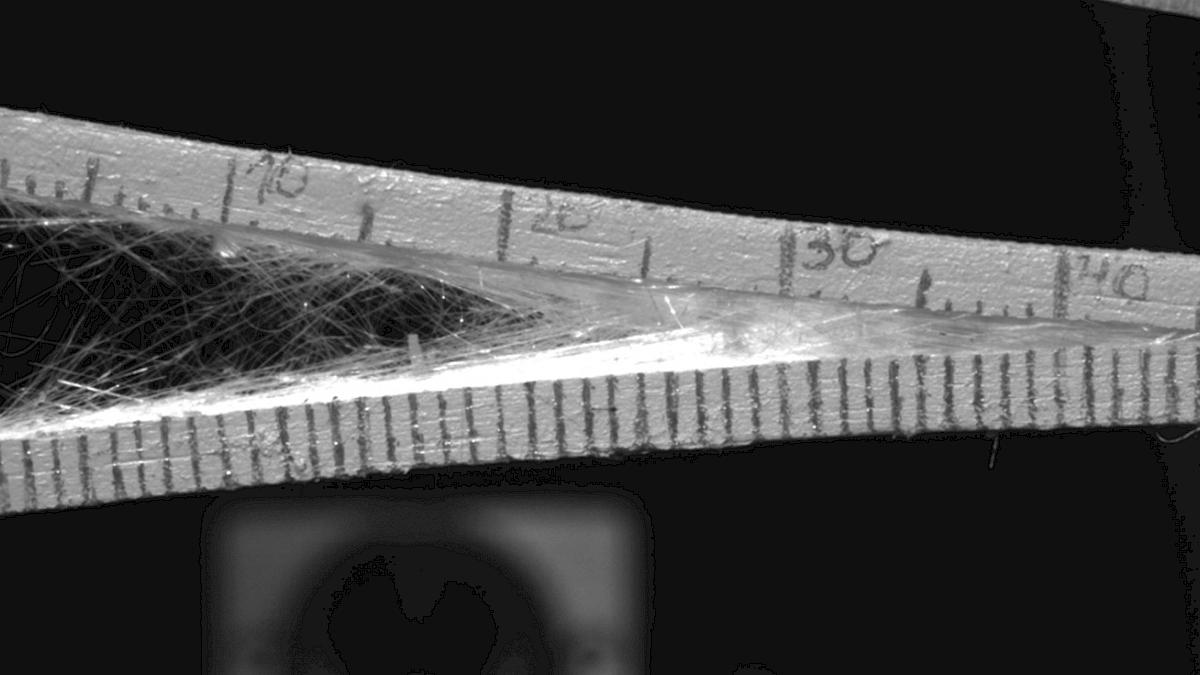

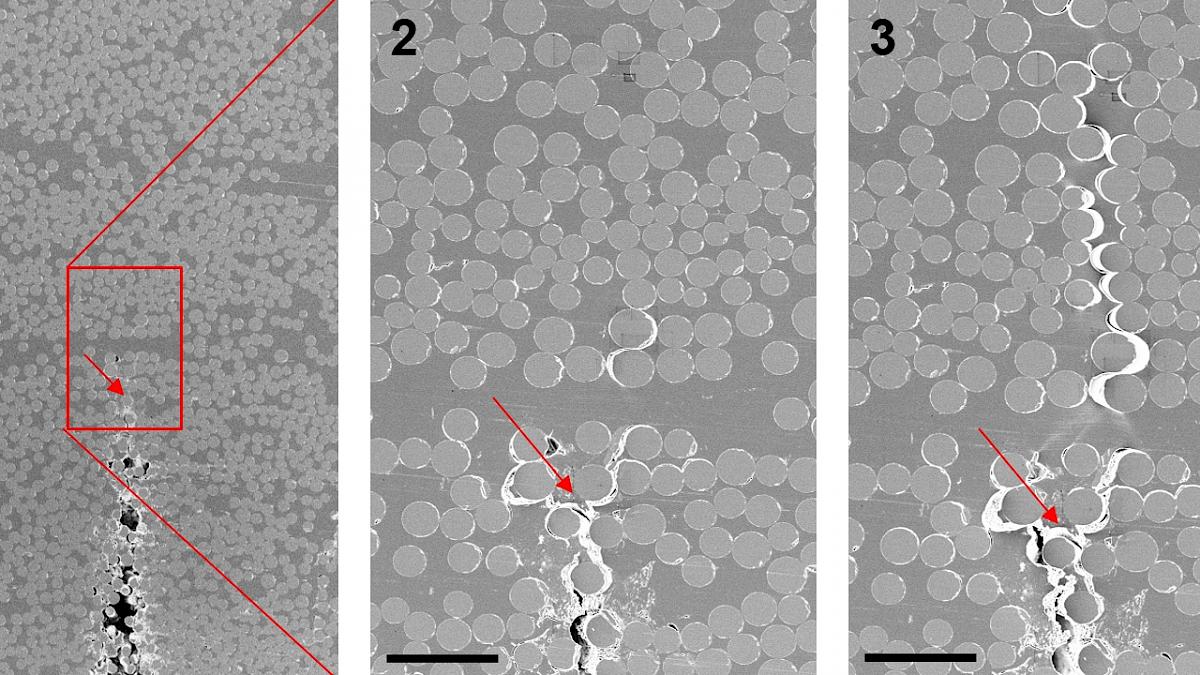

Standardized as well as tailored tests and evaluation procedures for the investigation of the material performance are our basis to develop the best combination of reinforcement fibers and polymer matrix for each application. Additional combined experimental and analytical investigations help us to improve the basic understanding of the microscopic structural behavior of lightweight fiber reinforced polymer materials.

Lightweight design

Our own efficient laminate optimization algorithms allow to arrange the fiber reinforced polymers at the best place and to orient them in the optimal direction. Based on this we develop lightweight and cost efficient patched laminate structures that can be manufactured with a minimum of cut-offs as well as outstanding lightweight designs made from combinations of fiber reinforced polymers with additive manufactured elements.

Manufacturing processes for fiber reinforced polymer structures

In our research projects, we are supporting the development and optimization of robust and fast processes for lightweight fiber reinforced polymer structures with thermoplastic as well as with thermoset matrix systems.

Integration of functions

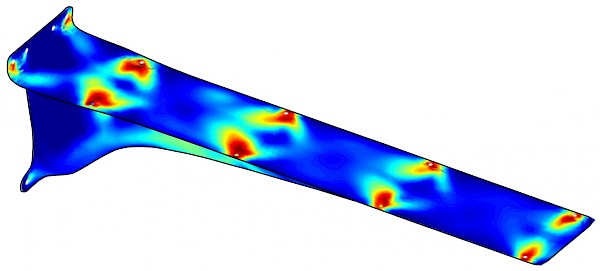

Fiber reinforced polymer components show an outstanding potential to integrate functions directly into the structure what is an elegant way to reduce at the same time the weight and the costs. One of our current research activities is focusing on passive damping approaches like particle dampers, which allow a robust and lightweight damping of structural vibrations.

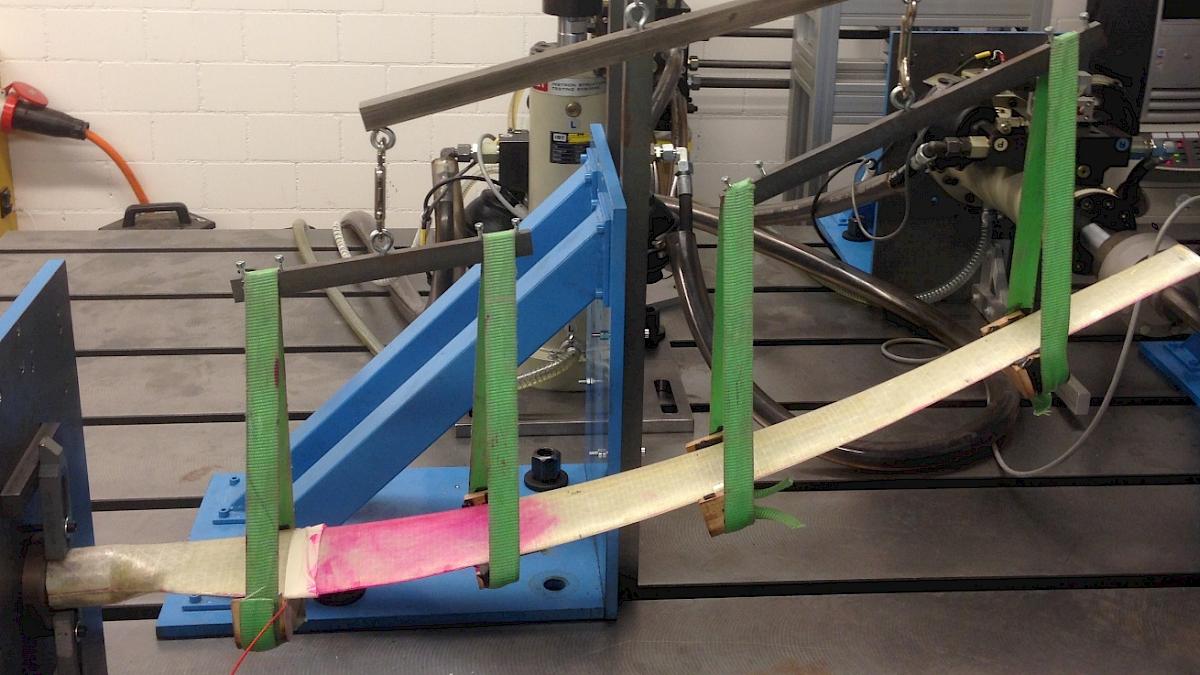

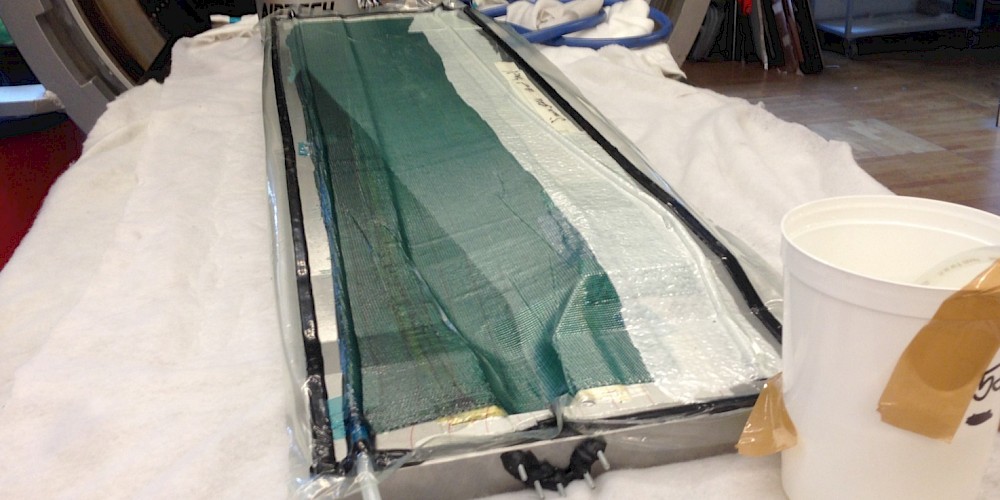

Panel made of carbon fiber reinforced polymers with particle dampers in a vibration test setup