Over 100,000 machine tools in Switzerland convert several kilowatts each from electricity into heat. They thus impair the quality of the workpieces and cause moist and warm air in workshops. Modern manufacturing therefore pursues the goal of the cold factory: energy-efficient, precise, productive. High-quality materials such as steel, aluminium or composite materials contain a lot of grey energy. The skilful use of semi-finished products, process chains from forming and machining or the combination with additive processes reduce material consumption and obsolescence is prevented with demand-oriented production.

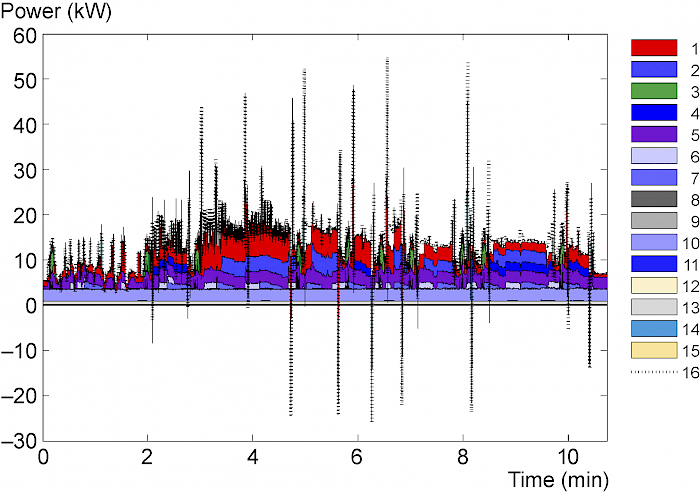

Performance measurement of machine tools

Energy savings in production machinery are not obvious. Rule-based procedures exploit only part of the improvement potential. By means of multi-channel measuring technology, all essential consumers of a machine can be detected simultaneously during operation. On this means, effective improvement measures can be derived.

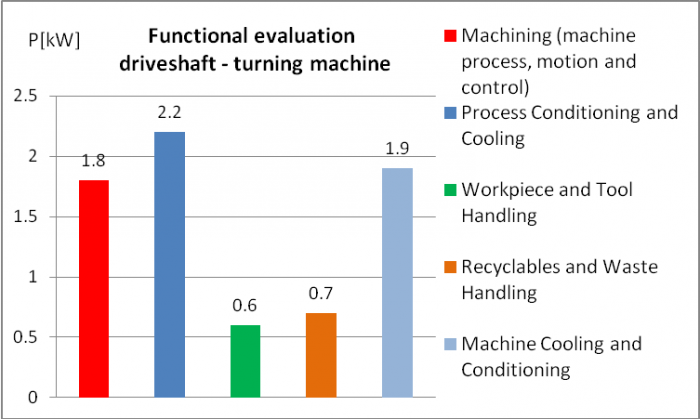

Function-related energy analysis

Industrial production is associated with energy consumption, but more is not always better. It is important that energy is used to create value instead of wasting it. The function-related analysis, which has also found its way into the international standard ISO 14955, offers an analysis option. It assigns the energy to the various functions of a machine tool and thus opens up the view to the essentials.