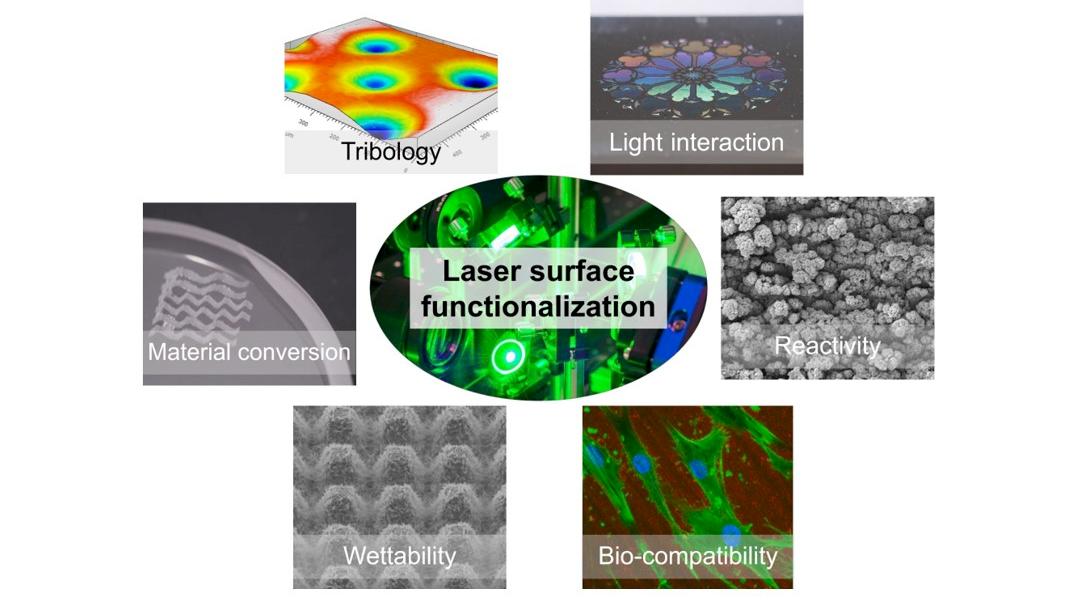

The focus in the research area of laser processing is on ultra-short pulsed (UKP) laser processes with the main applications "functionalization of surfaces" and "processing of ultra-hard materials". A well-equipped laboratory with ns, ps and fs lasers in power classes up to 200W and wavelengths from 355nm to 1064nm allows the processing of exotic materials with micrometer precision.

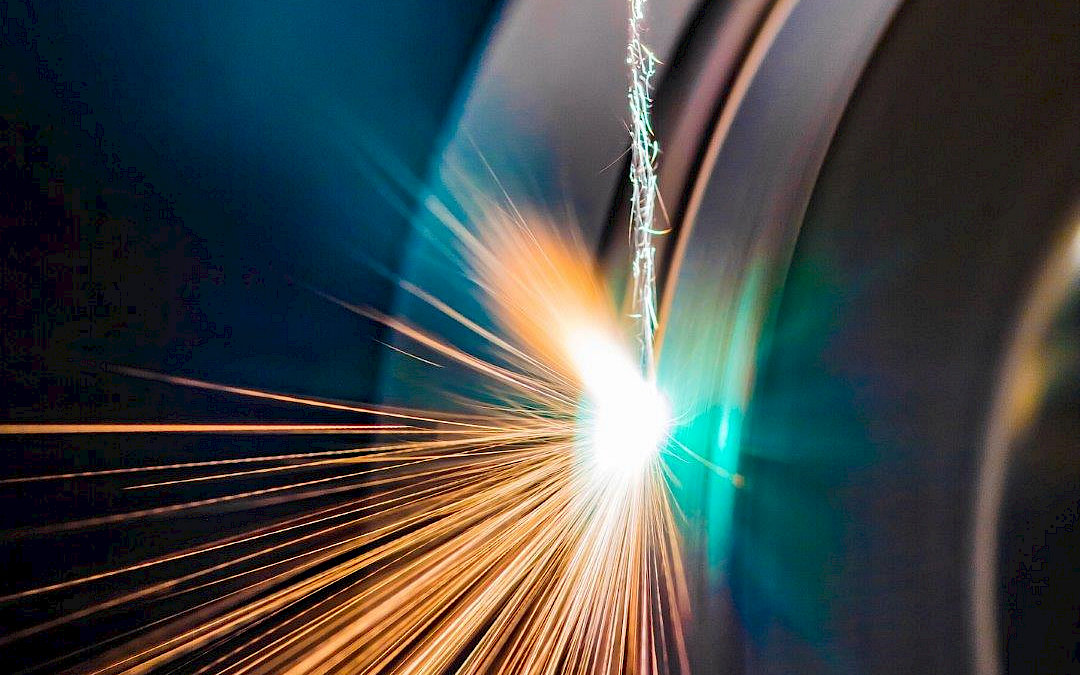

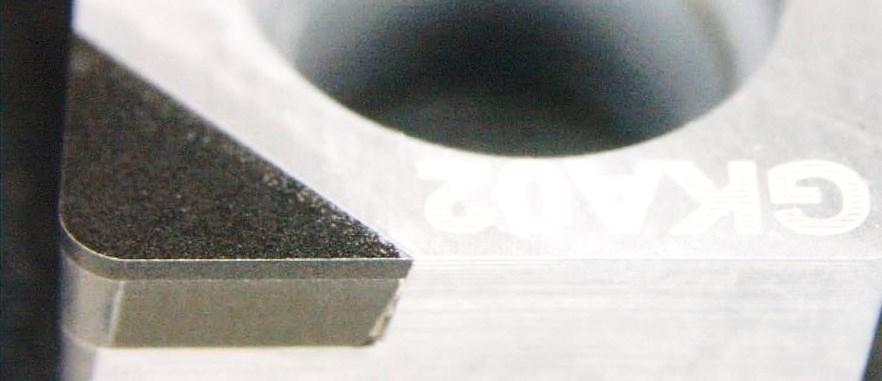

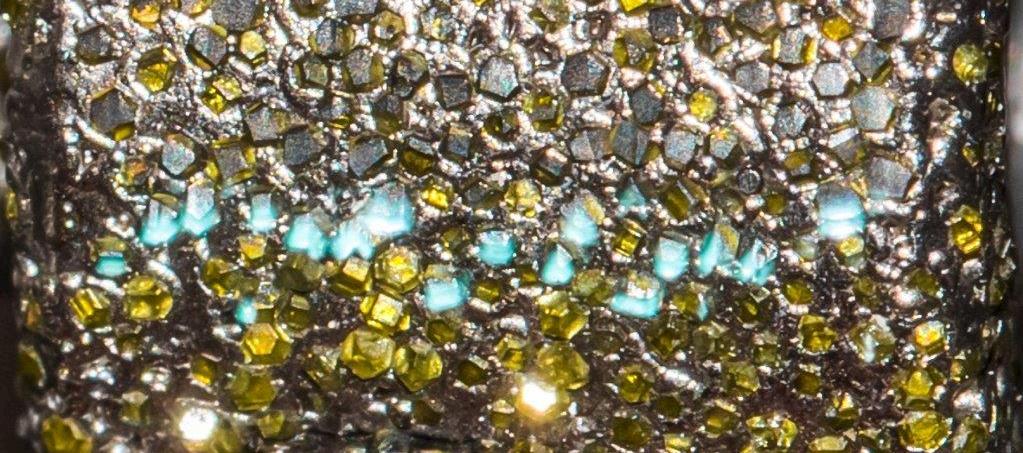

Machining of diamond grains and ultra hard cutting inserts

Besides the laser processing of tools with geometrically undefined cutting edges also cutting inserts and small milling and drilling tools out of ultra-hard materials such as natural diamond, polycrystalline diamond (PCD), cubic boron nitride (CBN) etc. are processed. The processing of the last-mentioned materials is only possible with ultrashort pulsed lasers since they enable the ablation by sublimation without significant heat flow to the crystal lattice. For this reason it is also called a “cold laser process”.

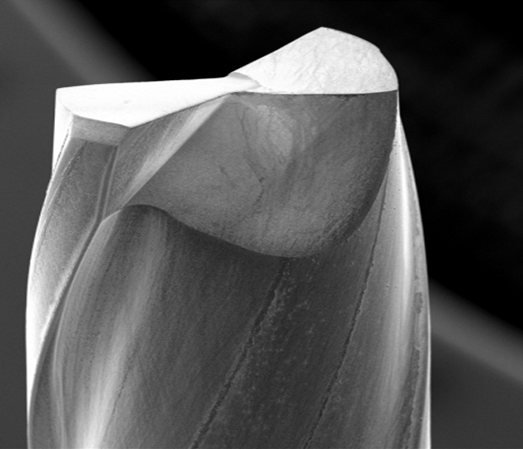

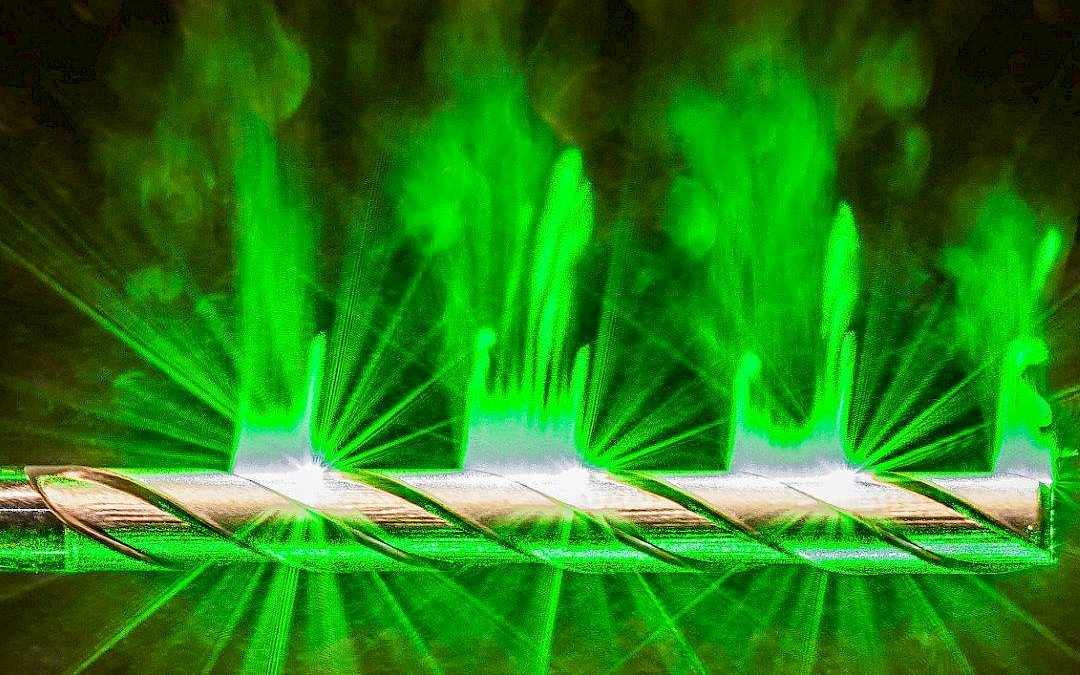

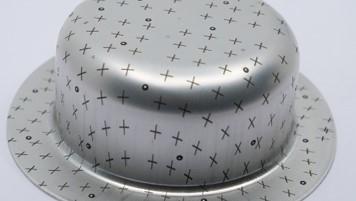

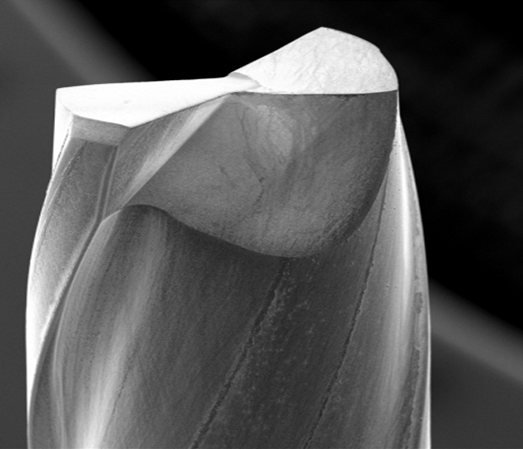

Manufacturing of micro drills

For the manufacturing of hard metal drilling or milling tools with diameters D < 500 µm, ultrashort pulsed lasers are especially suitable due to the force-free process and reduced processing temperatures. The achievable surface roughness is comparable to those obtained by grinding processes.

Manufacturing of micro drills

For the manufacturing of hard metal drilling or milling tools with diameters D < 500 µm, ultrashort pulsed lasers are especially suitable due to the force-free process and reduced processing temperatures. The achievable surface roughness is comparable to those obtained by grinding processes.