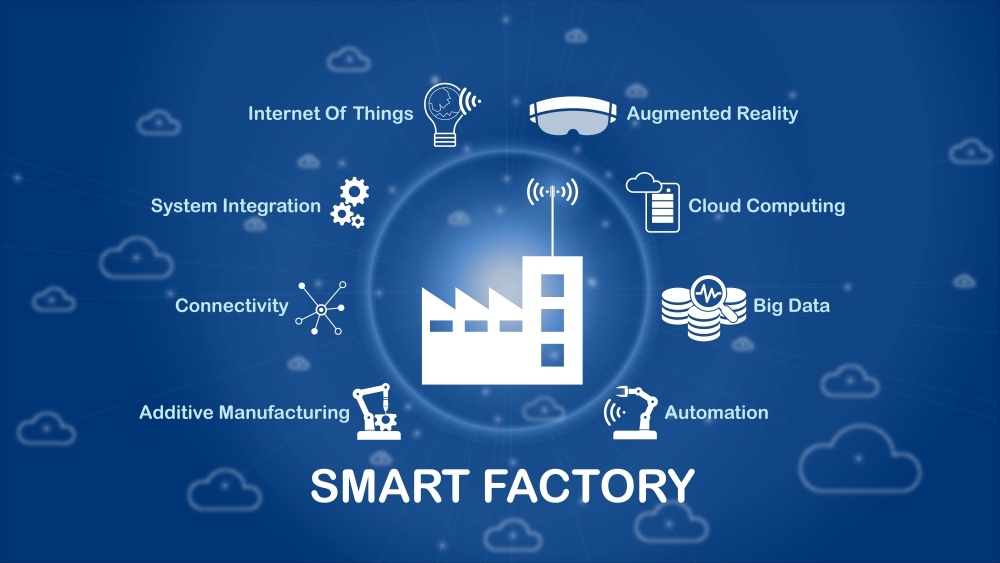

The realization of the "smart factory" is a future perspective of Industry 4.0. In the vision of an "intelligent factory", the production organizes and optimizes itself largely independently. The manufacturing processes are highly flexible and allow for the consideration of individual customer requirements up to the number of units 1. The prerequisite for flexible manufacturing is the networking of all systems involved in the manufacturing process: production machines, robots, measuring devices, logistics and IT systems, etc. The simple and secure data communication between machines and devices of different manufacturers is a central challenge and requires the definition of novel, internationally standardized interfaces and communication protocols. The individual subsystems of the production plant are designed as cyber-physical systems and communicate with each other via the Internet of Things. The product to be manufactured is equipped with a machine-readable code from the very beginning and communicates continuously with the production plant during the manufacturing process.