Mechanical engineering "Made in Switzerland" remains the successful basis for industrial value creation in the 21st century. Engineering know-how, controlled development processes, targeted and competent use of methods and high-quality mechanical manufacturing are necessary virtues. However, only by assisting machine tool users by in-process control, by advanced sensor technology combined with intelligent data handling, by the use of more powerful materials for key components or by optimized cost-effectiveness production, equipment from the high-wage country of Switzerland is competitive here and anywhere else in the world.

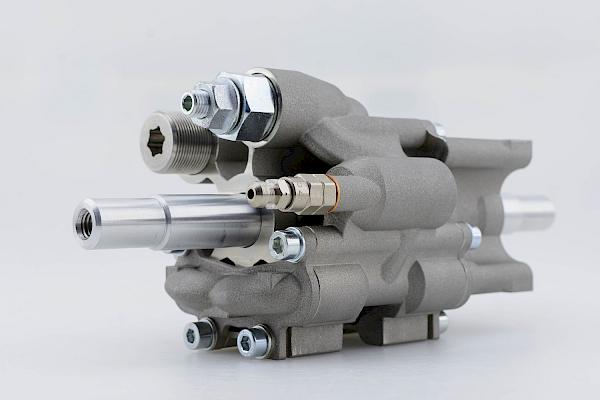

The choice of new materials can be motivated solely by one particular property, such as high specific strength. More often, however, such a fundamental choice favours materials that are at the same time highly performing and economical. The integration of additional functionality is of increasing importance. Integrated or immanent sensor technology and a high integration density in the original mould enable more intelligent production systems possible, and they eliminate subsequent, error-prone and time-consuming installation during assembly.

Highly productive automatic punching press

Today, automatic punching presses produce precision parts such as electronic plugs at up to 2000 strokes per minute. At accelerations of over 100 g, wear in the bearings increases drastically. For this reason, the inertial mass in the drive mechanism was reduced by a consistent lightweight design. For the ram, which carries the mobile upper part of the tool, the mass could be reduced by more than 70% with the use of carbon fibre reinforced plastic (CFRP). A special requirement was the fatigue strength: In one year, the ram undergoes more than 1 billion load changes.

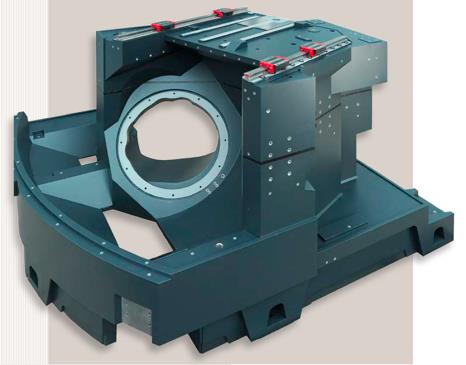

Highly integrated machine beds

Mineral cast (polymer concrete) has been used for several decades for beds in precision mechanical engineering. The continuously growing market share is not only due to the good properties such as high thermal inertia or good damping properties. Of particular interest are the high integration capability of a wide variety of machine functionalities, such as supply tubes and precision surfaces for mounting components, flexible scheduling with short lead times and cost-effectiveness through high added value in the original mould.